Changes for Plastic Manufacturers based in the United States.

In the 1950s and 1960s, made-in-China products were unheard of in the United States. Since the 1970s, however, the US has become increasingly dependent on over seas based manufacturing, particularly for plastic products. Plastic product imports are a $53 billion dollar industry, with nearly half of those imports coming from China. But these offshore imports are slowing down significantly, as Americans look to reshore product production back to US-based plastic manufacturers.

According to Forbes, no significant US trade partner has seen less trade growth than China since 2018. The Covid-19 pandemic further highlighted our country’s dependence on foreign plastic part products and ignited a movement toward the reshoring of plastic manufacturing. As of 2023, US plastic manufacturers like Integrated Molding Solutions have an advantage over offshore competitors for seven key reasons.

Working with plastic manufacturers in the US means faster time-to-market.

From plastic part production to shipping, manufacturing in the US is simply easier than manufacturing internationally. US manufacturers, like IMS, are readily able to acquire locally sourced feedstock and resin for plastic manufacturing and injection molding. Domestic manufacturing also means that it’s easier and faster to make design changes or product updates. Sea freight lead times from international manufacturers usually run four to six weeks at a minimum. Without the hassle of overseas shipping, US plastics manufacturers can reduce shipping lead times drastically. With domestic ground freight, we can often get your parts to you within a week. If needed, IMS can even overnight ship, completed plastic parts directly to you. Avoiding importing and exporting plastic material by working with a domestic manufacturer saves you time and money.

US based plastic manufacturers provide cost-effective and time-efficient transportation and shipping.

Reshoring manufacturing means faster time to market. IMS is experienced in shipping both domestically and internationally in the safest, most cost-effective way possible. We have a proven track record shipping finished goods all over the US, as well as to Mexico, Canada, South America, Asia, and Europe. For local or regional clients, we will gladly work with you to arrange pickup, cutting the cost of shipping entirely. For shipping in North America that isn’t regional to IMS, we work with reputable freight forwarders to ensure your plastic products make their way to your distribution site safely and on time.

Products made by offshore plastic manufacturing companies are subject to high tariffs.

Currently, tariffs on Chinese imports stand at 7.3%, which does not include the additional 25% tariffs on any plastic mold made in China. Further, labor costs in China have risen significantly over the last two decades. Today, Chinese labor costs fall within pennies on the dollar of labor costs in the US, and rarely come with the benefits and quality-assurance American labor provides.

Reshoring manufacturing enables ease of communication and in-person check-ins.

Differences in language, culture, and time zones are all barriers when it comes to offshore manufacturing. Working with trusted American plastics manufacturers resolves these issues. IMS takes that a step further with our Client Portal, which allows you to see up-to-the-minute details about the progress of your plastic fabrication project.

Communication with customers is our specialty. We pride ourselves on delivering the highest-quality plastic products to meet your needs. We also welcome customers to visit our manufacturing plant to check on their plastic production in person. This kind of visit would be extremely challenging to make to most offshore manufacturers. At IMS we provide full transparency throughout the plastic manufacturing process.

US Plastic Manufacturers like IMS ensure that your privacy and intellectual property are protected, providing peace of mind no found with offshore companies.

IMS protects your designs and ideas, while providing clear guidance on how to improve your plastic part designs to ensure cost-effectiveness as well as high quality and functionality.

The environmental benefits of reshoring manufacturing are profound.

When all components of the plastic manufacturing process are taken into consideration, it is clear that reshoring manufacturing is the most sustainable option for the planet. Then the final plastic product must be shipped back to North America. This creates a massive carbon footprint for any plastic product made in China. Further, US energy sources are cleaner than those in China thanks to strict US environmental laws. This is yet another reason to reshore plastic manufacturing. If sustainability is a priority to you, IMS is experienced in a number of sustainable plastic options and manufacturing processes. We work with recycled plastic and reduce plastic waste whenever possible.

Finally, manufacturing with Integrated Molding Solutions means you can take pride in quality, American-made consumer goods.

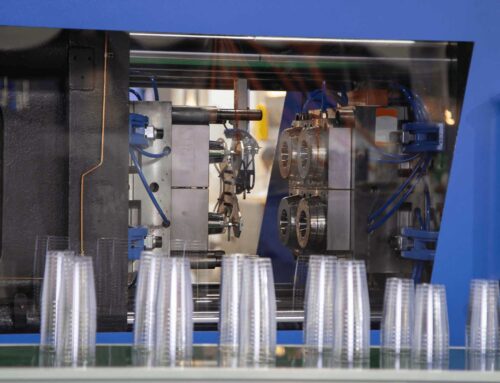

The US employs a skilled workforce made up of competent, trade-educated technicians. IMS engineers are experienced in the plastic manufacturing process as well as in exceptional customer service. Our capable workforce coupled with the manufacturing technology infrastructure available to US plastic manufacturers guarantee that your plastic parts are produced to the highest standards. Further, US regulations ensure quality control. Regular inspections of manufacturing plants meant that work and production standards are upheld. Working with US manufacturers also allows for total part customization. IMS specializes in customized molds and parts, and works with you to bring your vision to life.

Integrated Molding Solutions is one of the leading manufacturers of plastic parts and plastic injection molding in the US. We are proud to be an American SBA-certified Woman-Owned Small Business.