IMS Relocates: Elevating Custom Molding Solutions

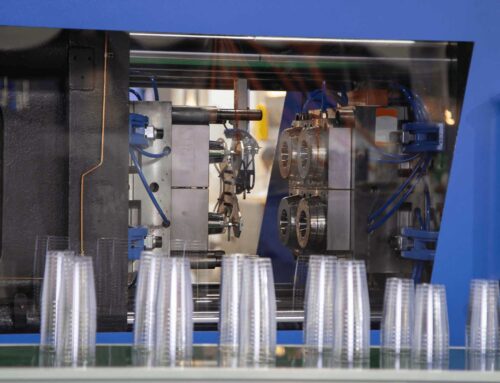

Integrated Molding Solutions (IMS) is excited to announce our recent relocation to a new facility. This move enhances our injection molding capabilities. As specialists in manufacturing and distributing custom injection molding plastics and 3D printing prototypes, this move represents our commitment to continuous improvement and customer satisfaction.

Our new space allows us to maintain the flexibility that customers value while streamlining processes and advancing technologies.

In this Q&A, we’ll share insights into our relocation journey, its benefits to customers, and how this move positions IMS for future growth in the plastics manufacturing industry. Join us as we explore the newest chapter in our mission to provide quality custom molding solutions.

Q: What was the primary reason for relocating IMS?

A: We ultimately saw this as an opportunity to establish a new, more modern facility. The relocation allowed us to create a more efficient layout that optimizes machine placement.

We’re now able to fit the same amount of equipment in less space, leaving room for future automation and additional equipment.

Q: How does your new location differ from your old location?

A: We downsized from 30,000 to 20,000 square feet, but the new space is more efficient. Our old building had various additions of different sizes that created layout challenges and increased transit time for moving parts from the molding floor to assembly, slowing down throughput. The new rectangular building allows for a more centralized, open-concept operation with fewer bays.

Previously, we had two molding floors, one climate-controlled and one not, which required process adjustments when moving tools between areas. Now, all machines are on the same floor with consistent environmental conditions, which is a key aspect of our lean manufacturing approach.

Q: How does closer proximity to the airport and the shipping channel benefit you and your customers?

A: Being closer to George Bush Intercontinental Airport (IAH) and the Houston Ship Channel is crucial since we primarily export our parts internationally.

The new location puts us closer to our freight forwarding partners, primarily located near the airport for similar reasons. This reduces transit time and decreases variables when arranging pickups or deliveries, ultimately enhancing our plastic manufacturing efficiency and reducing customer costs.

Q: How does the relocation align with your short-term and long-term business goals?

A: In the short term, the move addresses concerns over the physical condition of the previous facility. Similar to getting a new car, we now have lower maintenance and overhead costs, which is part of our drive to remain competitive. As one team member put it, “As the world has been changing, we realize that we have to change as well. A great way of getting that mindset correct is to physically change where you’re doing this.”

In the long term, the modular aspect of our new setup makes us inherently scalable. While we may have less physical space in the new building, the layout can be replicated in additional facilities as we grow, setting us up for effective production optimization in the future.

Q: How has your staff reacted to the move?

A: The response has been overwhelmingly positive. Since the move was only 8-10 miles, it didn’t significantly disrupt anyone’s commute, and some employees now have a shorter drive.

Everyone appreciates the fresh break room, new shop floor, and more efficient layout. Due to our reevaluation of equipment placement, we’re already seeing improvements in employee morale and throughput, particularly in assembly production.

Q: What challenges did you face during the relocation process, and how did you overcome them?

A: Planning was our biggest challenge. We had to forecast orders and overproduce inventory to minimize downtime. Our team’s flexibility was crucial. Everyone wore multiple hats, taking on tasks outside their job descriptions to complete the move quickly and efficiently.

The international volatility of freight coinciding with our move created additional complications, as information communicated to customers could become outdated within hours. Maintaining our high level of customer service during the transition was challenging, but our molding solutions team rose to the occasion.

Q: How do you plan to promote your new location to attract both existing customers and new customers?

A: We’re now in a building we can be proud of. After years of working in an old building with decades of wear and tear, we can stop asking customers not to judge us by our cover. We’re now in a space that makes us proud.

In-person visits are much more appealing, and we’re updating photos for our website to showcase the new layout. We’ve also joined the Greater Houston Manufacturers’ Association and are considering hosting Lunch and Learns, site visits, or even a golf tournament to connect with the local manufacturing community.

Q: Looking to the future, are there any new offerings, equipment, or technology that you’re excited to see coming down the road for your new facility?

A: The open design of our production floor makes it much easier to implement internet connectivity throughout the plant. We’re exploring web-connected monitoring systems that alert supervisors via text when a machine goes down, helping us maintain maximum uptime.

We’re also considering automation solutions, including robots, vision systems, and inspection equipment, as part of our commitment to lean manufacturing principles.

The new facility gives us more flexibility in the size of machines we can accommodate. While there may be a cap on the number of machines on the floor at once, we can more easily incorporate larger 500-600 ton machines as customer demands evolve.

The new facility gives us more flexibility in the size of machines we can accommodate. While there may be a cap on the number of machines on the floor at once, we can more easily incorporate larger 500-600 ton machines as customer demands evolve.

The move will also help us more easily transition toward certifications like 5S and Lean 6 Sigma, reinforcing our focus on quality management solutions and production optimization.

At Integrated Molding Solutions, we’ve always believed that we’re not just manufacturing custom injection-molded parts. We’re building our reputation in the global marketplace. Now we’re proud to have a space that reflects our commitment to quality and precision in our work.