Why Houston is the Ideal Location for Manufacturing Solutions

When it comes to injection molding, location can make a substantial difference in cost, accessibility, and efficiency. Texas, particularly Houston, offers distinct advantages that make it a prime hub for manufacturing, including injection molding.

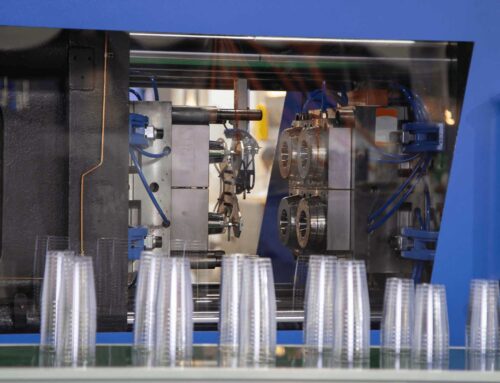

Integrated Molding Solutions (IMS), located in Houston, Texas, leverages these unique benefits to deliver high-quality, cost-effective injection molding services with a local touch. Here’s how choosing injection molding in Texas with IMS can benefit your business.

The Big Picture: Advantages of Texas Manufacturing

The state of Texas, especially the Houston area, is strategically positioned as a powerhouse for manufacturing. This advantage extends to a range of industries, including oil and gas, technology, and high-precision manufacturing. Houston’s location, combined with IMS’s local partnerships and in-depth experience, helps companies keep their entire production process local, reducing transportation costs, lead times, and dependence on long supply chains.

During recent global supply chain disruptions, such as the COVID-19 pandemic, businesses with locally-based manufacturing partners were better positioned to navigate challenges. IMS’s location in Texas allows us to provide a stable, dependable source for injection molding, protecting customers from the delays and added costs that international shipping disruptions can bring.

Proximity to the Port of Houston

One of the most significant advantages of manufacturing in Houston is access to the Port of Houston, one of the largest commercial ports in the United States. The port facilitates easy receipt of international shipments and provides a convenient gateway for importing raw materials and exporting finished products. Additionally, Houston’s proximity to Mexico and efficient trade routes with China make it simple and cost-effective for IMS to obtain materials and components from key suppliers abroad.

The Port of Houston’s extensive connections ensure faster shipping times and a reliable flow of materials, enabling IMS to maintain shorter lead times and keep production schedules on track. This level of connectivity is a game-changer, especially for clients with intercontinental needs.

Lower Overhead and Competitive Pricing

Houston’s lower property costs compared to other major U.S. manufacturing hubs allow IMS to maintain competitive pricing without sacrificing quality. Lower overhead in the Houston area means that we can pass on cost savings to our clients, offering a more affordable part price and reducing overall manufacturing expenses.

Serving Diverse Industries Across Texas

Houston’s economy thrives on a mix of industries, and IMS has built a solid foundation of expertise in several key sectors:

| Oil and Gas

Houston is often referred to as the energy capital of the world, home to numerous oil and gas headquarters. IMS has extensive experience in delivering high-quality injection molding services to major corporations in this industry. Our capabilities meet the specific needs of oil and gas clients, who often require robust, high-tolerance parts for demanding applications. |

Medical

Precision is critical in the medical field, where even minor variations can have significant consequences. IMS’s facilities and equipment enable us to produce parts with incredibly tight tolerances, making us a trusted partner for medical companies in Texas. From medical-grade plastics to advanced molding techniques, IMS offers solutions that are designed with patient safety and industry standards in mind. |

Technology

Houston has a growing tech sector, and our injection molding capabilities are well-suited to meet the needs of this industry. We work closely with our technology clients to create custom parts that meet exact specifications and rigorous quality requirements. |