The Importance of Rapid Prototyping for Plastic Design & Manufacturing

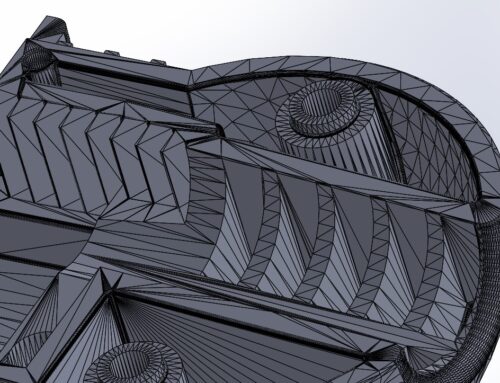

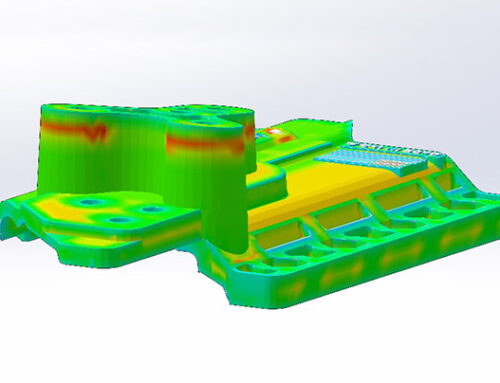

Integrated Molding Solutions plastic experts understand the critical role that rapid prototyping plays in plastic parts and product development. 3D Printing product prototypes allow businesses to iterate, test, and refine their designs before moving forward with tooling and high-volume additive manufacturing. With a focus on quality, efficiency, and customer satisfaction, our 3D Printing and rapid prototyping process enables you to transform your concepts into 3D printed parts for functional testing quickly and cost-effectively.

Integrated Molding Solutions Advances Our Rapid Prototyping Services

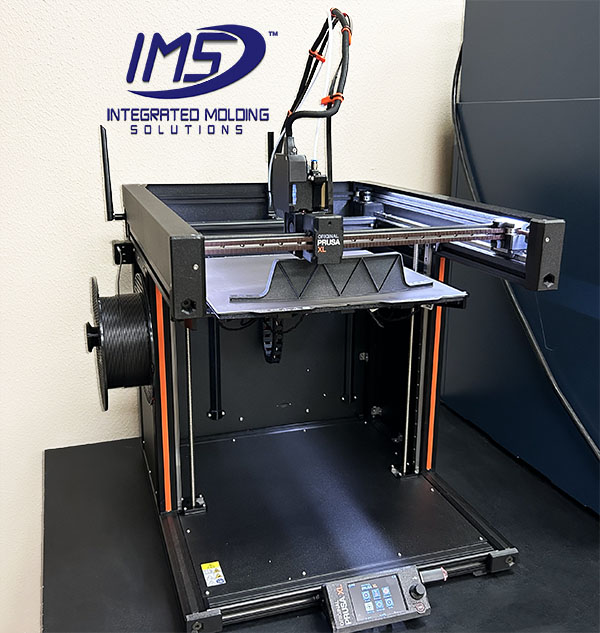

At IMS, we continue to expand our capabilities and efforts to provide environmentally responsible solutions for global demands in plastic. To do so, we strive to update our equipment and stay up to date on the most current technologies, materials, and plastic industry news. To grow our rapid prototyping capabilities and offerings, we have just added the new Original Prusa XL 3D Printer. This brand new, larger FDM 3D Printer will allow us to provide larger and more precise rapid prototypes to customers. Our new Prusa XL 3D Printer will improve our product design abilities of larger injection molding products and enhance the prototyping and tooling specifications we can reach.

Rapid Prototyping Capabilities with the Prusa XL 3D Printer.

The Original Prusa XL 3D Printer is a large-scale CoreXY 3D printer that has a build volume of 14.7” x 14.7” x 14.7” (36x36x36 cm). The 3D Printed Prototype quality is enhanced with the new modular bed design, and automatic first layer calibration, providing a perfect first layer. Rapid Prototyping will be further improved with the expansion of up to five tool heads with an extremely accurate tool changer. The Original Prusa XL 3D Printer supports an expansive range of plastic materials allowing your prototype to be a more functional representation of the finished product. From PLA to Polycarbonate or Polypropylene, IMS can provide you with precision 3D-printed prototypes.

Prusa XL 3D Printer Specs:

- Printer design: Core XY

- Build volume: 360×360×360 mm (14.17’’×14.17’’×14.17’’)

- Filament diameter: 1.75mm, wide range of thermoplastics supported (including, but not limited to PLA, PETG, ASA, ABS…)

- Mesh Bed Levelling: Load Cell-based fully automatic first layer calibration with no Live Z adjustment

- The Original Prusa XL 3D Printer Video

Contact Integrated Molding Solutions today to discuss your plastic product design or any Rapid Prototyping Needs.

Integrated Molding Solutions is your trusted partner for anything related to additive manufacturing plastic products. With our commitment to quality, speed, and customer satisfaction, our rapid prototyping services help you streamline your product development and provide a functional prototype for functional testing. Let IMS’s 3D printing service bring your ideas and final product to life with our precision injection molding and additive manufacturing. Experience the power of Integrated Molding Solution’s rapid prototyping services and take your plastic innovations to new heights.