Focused Areas of Precision Injection Molding: Design, Manufacturing, and Quality Control

Precision is a crucial element in the world of manufacturing, and IMS engineers have the expertise to achieve precision consistently. When it comes to plastic injection molding, precision is often required for the form, fit, and function of a plastic product or part. At IMS, we specialize in precision injection molding, employing state-of-the-art technologies and our years of experience to deliver consistent, high-quality plastic parts. Our precision-focused approach includes design for manufacturing (DFM), tooling, production processes, and quality assurance and control.

Precision in Plastic Design for Injection Molding

Precision begins with the design phase. Our engineering team thoroughly reviews part drawings, evaluating them for molding and tooling issues. We examine features that may pose challenges for molded plastic, such as undercuts, texture requirements, draft angles, and thickness. By addressing these concerns early on, we ensure that the final design will meet the required form, fit, and function while optimizing the manufacturability of the part.

DFM Tooling

To simplify the tooling process, IMS engineers utilize the principles of Design for Manufacturing (DFM). By employing intelligent mold design strategies, we can achieve complex geometries using simple precision tooling methods. Our goal is to engineer cost-effective tooling solutions while maintaining the highest levels of precision and delivering on customer requirements. By collaborating closely with toolmakers, we guarantee that the tooling is precisely crafted to meet the specific requirements of each project. We also perform routine maintenance and upkeep on each precision mold to ensure mold longevity.

Precision Injection Molding Process Control

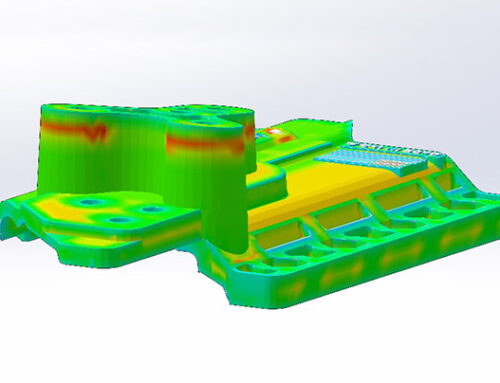

Our injection molding process is guided by an unwavering commitment to precision and consistency. Customer satisfaction is our primary goal, and we ensure that the tools and processes we use serve that goal. We utilize hydraulic and hybrid hydraulic electric machines that offer exceptional precision, as opposed to an injection molding machine focused solely on speed. By leveraging our expertise in process control and material behavior, we can achieve precise and consistent results.

From the very beginning of a project, IMS engineers identify the key parameters required to establish and maintain consistency throughout the manufacturing process. We adjust injection mold temperature, material temperature, injection speed, and injection pressure to optimize the mold cavity filling and ensure the parts come out exactly as intended and avoid pitfalls like sink or shrinkage. Our mastery of process control and material behavior allows us to minimize unnecessary post-processing requirements, such as trimming, and deliver high precision parts that meet the strictest tolerances. For necessary post-process treatments like assembly, painting, or fastening, IMS upholds our precision injection molding standards.

Prototyping and Validation

To provide customers with a clear understanding of the final product, IMS employs advanced 3D printing technology. Our precision 3D printers produce prototypes that closely resemble the actual model dimensions. This allows customers to visualize and test the part’s form, fit, and function before moving into production. In alignment with our goal of customer satisfaction, IMS utilizes the highest quality 3D printers to deliver prototypes with tight dimensional tolerance.

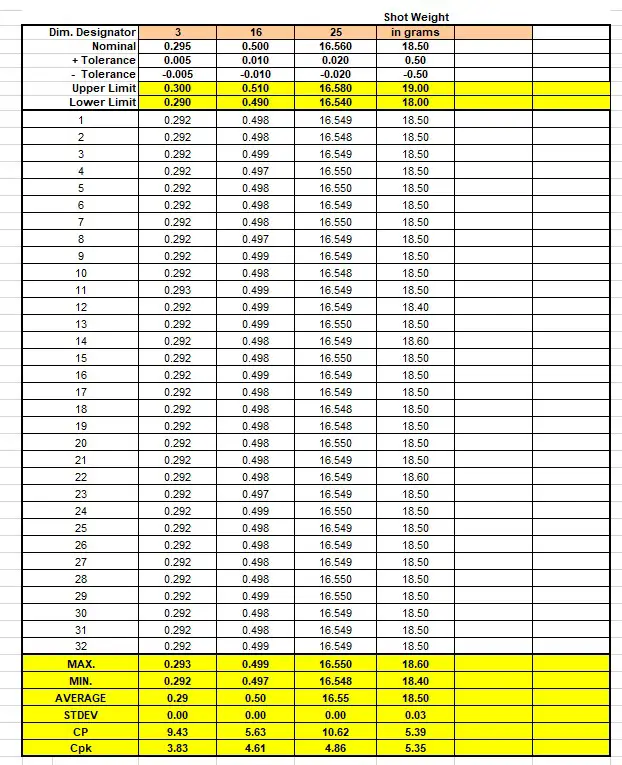

Tool Verification and First Article Inspection

Before proceeding to production, IMS experts conduct thorough tool verification and First Article Inspection (FAI). The toolmaker runs samples and ships them to IMS for evaluation. We measure the tolerances of these samples to ensure that the injection mold can consistently produce precision plastic parts within the given requirements. Once the customer approves the samples, the mold is shipped to our facility for FAI.

During the FAI process, we utilize the Cp/Cpk (Process Capability Analysis) method to assess the precision and consistency of the parts. By running our own sample lot and checking the primary dimensions of each sample injection molded part, we can determine the mold’s capability to produce parts that meet the desired specifications. Our target Cp/Cpk value is greater than 1.33, and we are proud that our regular results exceed this threshold, ranging from Cpk 2.5 to 3. This level of consistency assures our customers that each plastic part will be consistently produced with the utmost precision.

Production and Quality Control

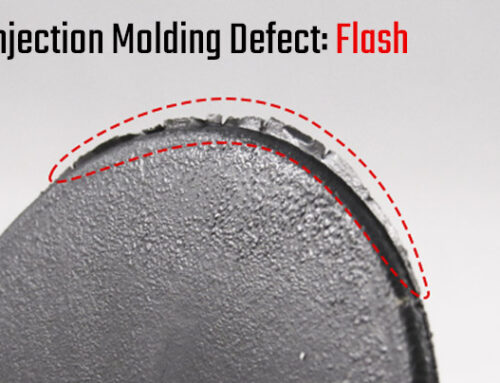

Our commitment to precision extends to our production processes. We employ proactive Quality Assurance (QA) techniques to prevent defects and rejections. By identifying potential risks and areas of improvement, we ensure consistent and high-quality production. Our operators perform regular inspections throughout the production run, and we conduct maintenance on molds and injection machines to ensure longevity and precision.

In the event of a defective plastic part, we implement reactive Quality Control (QC) measures. We employ a corrective action process, starting with a corrective action report to contain the issue and prevent further defective parts from being released. Through root cause analysis, we identify the underlying cause of the defect and implement the necessary corrective solutions, such as process adjustments or molding machine operator training. This information is then fed back into our Quality Assurance system to further refine our precision plastic injection molding process and maintain the highest level of dimensional accuracy in each plastic component we manufacture.

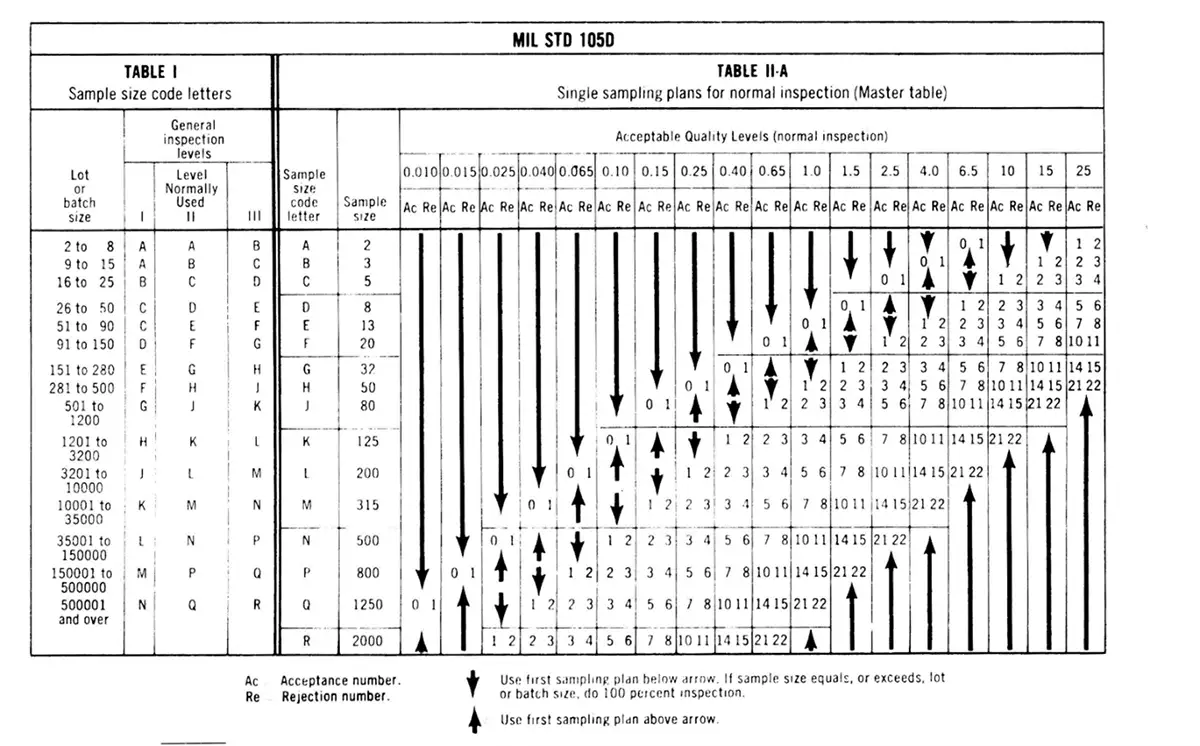

Acceptable Quality Limits

In order to maintain the highest standards of quality, IMS utilizes the concept of Acceptable Quality Limits (AQL) based on Mil standard 105D. AQL is a heavily utilized sampling plan across our manufacturing processes. It enables us to conduct Out of Box Audits (OAB’s) and statistically assess the quality of finished products. By referring to the AQL chart (see below), we determine the number of parts in a lot that need to be tested to ensure compliance with quality standards. This rigorous sampling plan allows us to identify any potential deviations and take corrective actions promptly, ensuring that our products consistently meet the desired level of precision. By employing AQL, IMS further strengthens our commitment to making parts right the first time and upholding our reputation for delivering precise, high-quality plastic components.

In order to maintain the highest standards of quality, IMS utilizes the concept of Acceptable Quality Limits (AQL) based on Mil standard 105D. AQL is a heavily utilized sampling plan across our manufacturing processes. It enables us to conduct Out of Box Audits (OAB’s) and statistically assess the quality of finished products. By referring to the AQL chart (see below), we determine the number of parts in a lot that need to be tested to ensure compliance with quality standards. This rigorous sampling plan allows us to identify any potential deviations and take corrective actions promptly, ensuring that our products consistently meet the desired level of precision. By employing AQL, IMS further strengthens our commitment to making parts right the first time and upholding our reputation for delivering precise, high-quality plastic components.

Our Precision Injection Molding Training and Certifications

Integrated Molding Solutions understands that precision and consistency require skilled operators who are well-versed in the intricacies of the molding process. To ensure that our team meets the highest standards of expertise, we provide comprehensive training programs for our employees. Through these programs, our operators receive in-depth knowledge about injection molding principles, machine operation, mold maintenance, and quality control procedures. We also offer opportunities for our employees to become certified operators, equipping them with the necessary skills and knowledge to handle complex molding projects with precision and efficiency. By investing in training, certification, and continuing education, we empower our team of industry veterans to deliver exceptional results and uphold the utmost precision in every aspect of our operations.

Integrated Molding Solutions understands that precision and consistency require skilled operators who are well-versed in the intricacies of the molding process. To ensure that our team meets the highest standards of expertise, we provide comprehensive training programs for our employees. Through these programs, our operators receive in-depth knowledge about injection molding principles, machine operation, mold maintenance, and quality control procedures. We also offer opportunities for our employees to become certified operators, equipping them with the necessary skills and knowledge to handle complex molding projects with precision and efficiency. By investing in training, certification, and continuing education, we empower our team of industry veterans to deliver exceptional results and uphold the utmost precision in every aspect of our operations.

For precision in plastic design and manufacturing, contact IMS today.

At Integrated Molding Solutions, precision is at the core of everything we do. From the initial design phase to the production process and quality control, we strive for consistency and accuracy in delivering high quality plastic parts. By employing cutting-edge technologies, adhering to rigorous quality control standards, and leveraging our expertise in material behavior and process control, we ensure that every part meets the required specifications. Partner with IMS for precision injection molding services that meet your needs, and experience the difference that true precision can make in your molded parts and products. Contact us today for additional information.