At IMS, we follow a straightforward process to design and manufacture high-quality, precision plastic parts. The goal of our plastic manufacturing process is to remove variables early on, allowing us to hone in on application requirements while keeping the project cost-effective. Whether you need simple or complex parts, our custom plastic parts manufacturing process is designed to streamline your project.

At IMS, we follow a straightforward process to design and manufacture high-quality, precision plastic parts. The goal of our plastic manufacturing process is to remove variables early on, allowing us to hone in on application requirements while keeping the project cost-effective. Whether you need simple or complex parts, our custom plastic parts manufacturing process is designed to streamline your project.

When it comes to plastic injection molding, the earlier we make design changes, the better. As we move through the process, making changes becomes increasingly costly and time-consuming. It’s much cheaper to make adjustments during the design phase than in the tooling phase. If you already have an approved CAD design and prototype of your custom plastic part, skip to Step 3.

Our Straightforward Plastic Parts Manufacturing Steps

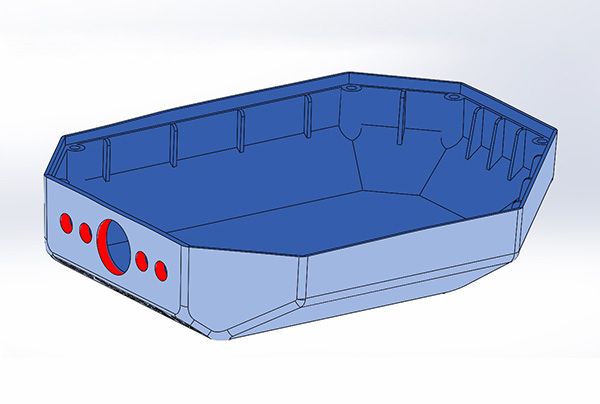

Step 1: Design

First, we work with you to understand the plastic product or part’s intent and application requirements. In order to move forward with the project, we need an approved engineering CAD file* and a drawing file (PDF) outlining tolerances, surface finishes, and textures of the custom plastic parts. If you already have an engineering CAD file, send it to us and we’ll move on to Step 2. If not, we’ll work with you to design the CAD file, using any sketches, descriptions, or specific requirements you have. If a physical plastic part already exists, we can reverse engineer it to create a detailed design. IMS can handle the design internally or collaborate with a partner designer.

*Note: An engineering CAD file (STEP or IGES) is necessary for injection molding. An STL file is only applicable for 3D printing and is not sufficient for quoting, modifying, or measuring for injection molding.

Step 2: Prototype

We create a prototype using the engineering CAD design, typically via 3D printing. CNC machining is another option. Then, we test the prototype to ensure it meets the design’s intended purposes and application requirements. If necessary, revisions are made to the design based on the prototype evaluation.

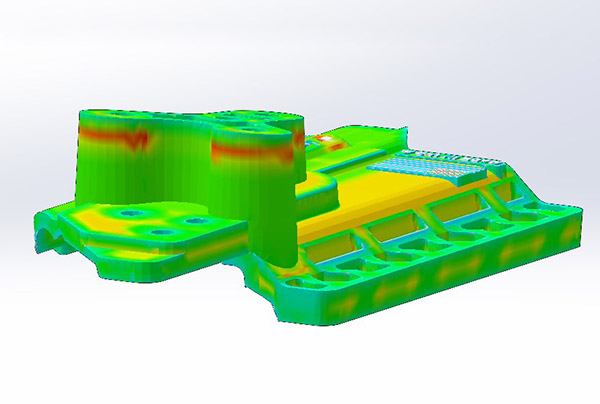

Step 3: Design for Manufacturability (DFM)

At this stage, the design is optimized for the chosen manufacturing method (e.g., injection molding, 3D printing, CNC machining), ensuring design suitability. We also finalize plastic material selection and determine production volume to optimize cost-effectiveness. If you’re looking for sustainable options, IMS offers biodegradable plastics and also works diligently to reduce our carbon footprint and plastic waste overall.

The DFM phase ends with an optimized part design suitable for application and manufacturing, with final approval for moving towards tooling. If changes need to be made, we go back to the prototyping stage to confirm suitability.

The first three steps—Design, Prototype, and DFM—are essential for providing you with an accurate quote. Once we have DFM approval, IMS will provide you with a detailed project quote.

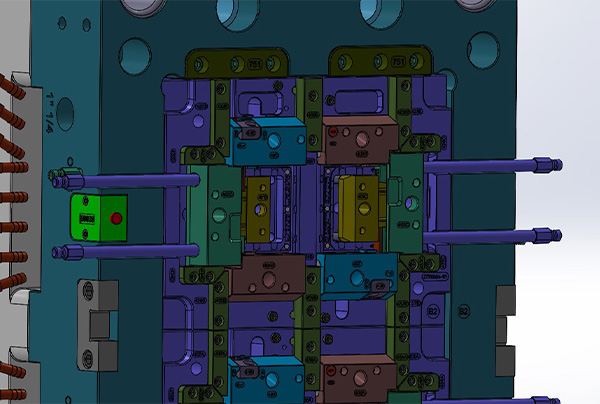

Step 4: Tooling – Mold Design and Mold Production

IMS partners with expert toolmakers both domestically and overseas. These partnerships allow us to provide our clients with precision molds customized to ensure plastic components form, fit, and function. The tooling experts confirm the part design for moldability before producing the mold. This ensures that the molten plastic will be shot into the mold correctly, helping to avoid defects like flash or sink. If there are any concerns with the design, we go back to the DFM process.

IMS partners with expert toolmakers both domestically and overseas. These partnerships allow us to provide our clients with precision molds customized to ensure plastic components form, fit, and function. The tooling experts confirm the part design for moldability before producing the mold. This ensures that the molten plastic will be shot into the mold correctly, helping to avoid defects like flash or sink. If there are any concerns with the design, we go back to the DFM process.

Step 5: Sampling

Using the new, custom mold, the toolmaker produces a short run of parts to evaluate. Those samples are then sent to IMS for evaluation. We compare them to the engineering drawings to ensure they meet tolerances and application requirements. Any molding defects are addressed, potentially adjusting the tool if needed.

Once we have approved the samples, the tooling has any last surface finishes added. The finalized injection mold is then sent to our Houston facility to enter production.

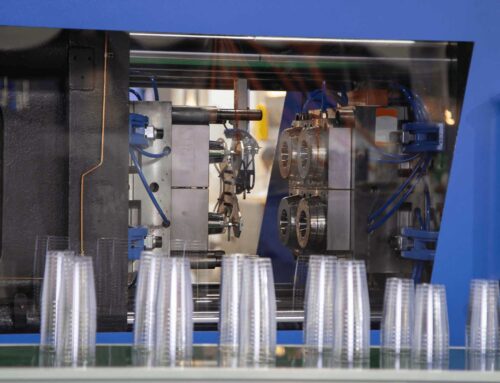

Step 6: Production

At this stage, IMS produces your fully functional, optimized parts at scale, ready for use in their intended applications. During the injection molding process, we ensure optimal cycle times to keep your project on time and on budget. We also offer a range of post-process services, including insert molding, pad printing, and parts assembly.

What stage are you at in the plastic part manufacturing process?

At Integrated Molding Solutions, we pride ourselves on delivering reliable and efficient plastic part manufacturing solutions for our clients. The process outlined above ensures that each plastic component we produce meets the highest quality and performance standards while keeping your costs low and your project on time. Our injection molding service is comprehensive, and we pride ourselves on manufacturing plastic parts with precision to meet your needs. Contact us today to start the plastics manufacturing process.