The Basics of Injection Molding Wall Thickness

Injection molding is a versatile and widely used manufacturing process for producing plastic parts and products, ranging from intricate medical devices to everyday consumer goods. One of the most critical factors influencing the success of injection molding is wall thickness. Wall thickness directly impacts the quality, cost, and performance of the final product. In this article, we will delve into the importance of wall thickness in injection molding, exploring how it affects the entire manufacturing process and the characteristics of the end product.

What Is Wall Thickness for plastic molded parts?

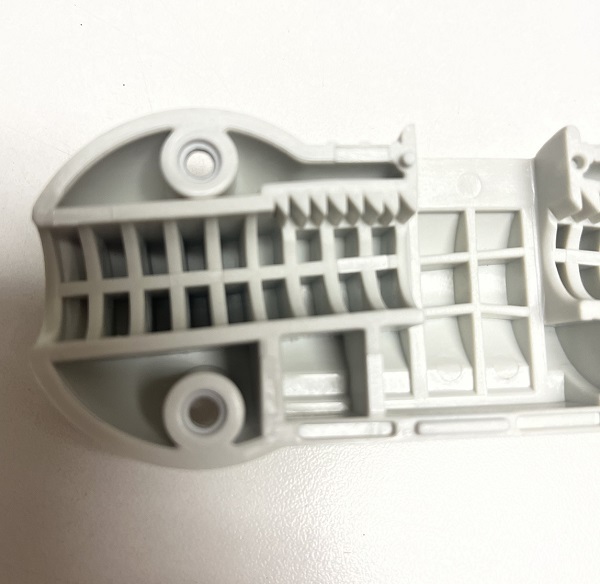

Wall thickness in injection molding refers to the thickness of the walls of a plastic part. It is measured as the distance between the part’s outer surface and its inner surface. Wall thickness is a fundamental design consideration for the injection molding process, that influences how molten plastic flows through the mold, cools, and solidifies to create the final product. Achieving the optimal wall thickness is crucial for producing high-quality parts that meet design specifications and perform their intended functions effectively.

Uniform Wall Thickness for Quality and Consistency

One of the primary reasons why wall thickness is so important in injection molding is its direct correlation with part quality and consistency. Parts with uneven wall thickness are more likely to exhibit defects such as warping, sink marks, or shrinkage. These defects not only compromise the aesthetics of the product but can also affect its structural integrity and functionality.

For instance, variations in wall thickness can lead to differential cooling rates during the molding process. Thicker sections of the part take longer to cool than thinner sections, resulting in internal stresses that can cause warping or distortion. By maintaining uniform wall thickness, manufacturers can minimize these issues and produce parts with consistent quality.

Impact on Cost Efficiency

Wall thickness also plays a significant role in the cost efficiency of injection molding. A well-designed plastic part with optimized wall thickness can save on material costs, reduce cycle times, and minimize the risk of defects, all of which contribute to lower production costs.

When wall thickness is excessive in certain areas of a part, it requires more material to be injected, increasing material costs. Additionally, thicker sections take longer to cool, extending cycle times and reducing production efficiency. Conversely, overly thin walls can lead to part weakness and higher scrap rates, as they are more susceptible to defects like short shots or voids.

By carefully considering and optimizing wall thickness in the design phase, manufacturers can strike a balance between part strength and material efficiency, ultimately reducing the overall cost of production.

Strength and Performance

The structural integrity and performance of an injection-molded part are closely linked to its wall thickness. In applications where mechanical strength is paramount, achieving the right wall thickness is critical. Parts with inadequate wall thickness may be prone to cracking, deformation, or failure under load.

On the other hand, overly thick walls can add unnecessary weight and bulk to a part, which is particularly undesirable in industries where lightweight components are essential. Striking the right balance ensures that the part meets its strength requirements while remaining lightweight and cost-effective.

Material Selection and Wall Thickness

The choice of material for injection molding also influences the ideal wall thickness. Different materials have varying flow properties and shrinkage rates during cooling. Engineers must consider these material-specific characteristics when determining the optimal wall thickness for a particular part.

Design Guidelines for Optimal Injection Molding Wall Thickness

To achieve the best results in injection molding, it’s essential to follow some design guidelines regarding wall thickness:

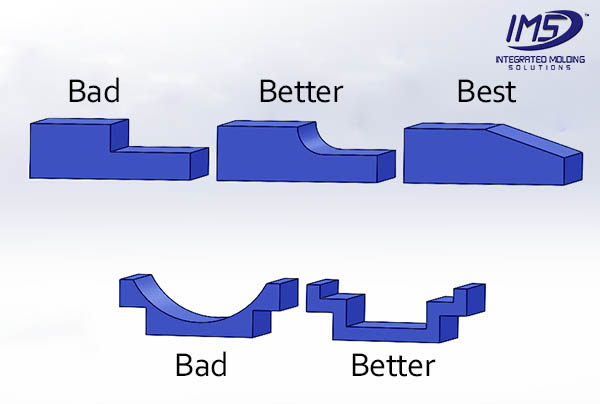

Maintain Uniformity: Strive for uniform wall thickness wherever possible to ensure consistent cooling and minimize the risk of defects.

Tapered Transitions: Use gradual transitions between thick and thin sections to reduce stress concentrations and the risk of sink marks.

Rib Design: When additional strength is needed, consider adding ribs or gussets rather than increasing wall thickness uniformly.

Material-Specific Adjustments: Be aware of material-specific requirements and adjust wall thickness accordingly.

Consult with Experts: Collaborate with experienced injection molding professionals, like Integrated Molding Solutions, who can provide valuable insights into optimizing wall thickness for your specific project.

Injection Molding Wall Thickness Overall Impact

In the world of injection molding, wall thickness is not merely a design parameter but a critical factor that impacts the quality, cost, and performance of the final product. By carefully considering and optimizing wall thickness in the design phase, manufacturers can achieve superior part quality, cost-efficiency, and mechanical performance. Whether you’re designing a simple consumer product or a complex industrial component, understanding the importance of wall thickness is key to successful injection molding.